Vision Systems set up in 2015 a new production unit dedicated to composite parts to respond to the growing need of its customers in terms of composite products integration for the aeronautic, helicopter and marine markets.

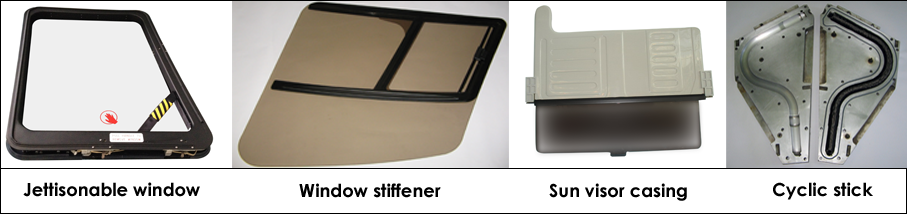

Vision Systems’ composite expertise in addition to that of mechanics and electronics enables the company to control the product development from beginning to end and to offer complete functional systems with breakthrough features. Complete window and door solutions for helicopters are part of Vision Systems’ products made of composite.

Composite processes include:

- Resin Transfer Molding (RTM) for cyclic sticks, window and sun visors stiffeners

- Thermocompression for sun visors’ casings, window frames

- Infusion for very large window frame

- Prepreg autoclave molding for sun visors’ casings

Composite, process for fabrication of high-tech components:

- Weight saving

- Excellent fatigue and corrosion resistance

- Increased damage tolerance

- High technical precision

- Improved damping for lower noise and vibration

- Reduced parts count achieved through single piece moulding, and lower operational costs